LEANWIND Newsletter - May 2017

With the project in its last year, activities have become very dense in results encompassing all the different steps of an offshore wind farm supply chain:

- improved designs of gravity based foundations and steel substructures;

- further development of novel vessel concepts;

- Health & Safety risk control measures;

- testing of installation activities for a Gravity Based Structure, a turbine lifting system and a remote presence robot for O&M activities;

- assessment of market, environmental and socio-economic impacts of the project innovations.

All of those outcomes will be presented at a wide range of relevant events across EU countries. Do not miss them and get back to us for any further information on the project developments!

All the best,

Jimmy Murphy

LEANWIND Coordinator

|

What is LEANWIND about?

Photo credit: UCC

LEANWIND is a four-year project co-funded by the Seventh Framework Programme of the European Union. It will bring cost reductions to the offshore wind energy industry through the application of lean principles to key aspects of an offshore wind farm and supply chain. It will do so by focusing on developing innovative technologies, procedures and tools that are directly applicable and beneficial to the industry in the short to medium term.

For more information, please visit: www.leanwind.eu

|

PROGRESS & RESULTS

Construction, Deployment and Decommissioning

The support structures and substructures necessary for offshore wind farms construction, deployment and decommissioning phases need to be improved. Among other objectives, this set of activities aims at ameliorating the temporary stability of structures during the deployment phase, designing new types of gravity bases to reduce installation time and at finding innovations concerning the seabed preparation. See the executive summary of:

Upcoming executive summary -due at the end of May 2017 on www.leanwind.eu/results: “Floating substructures design framework” (D2.5)

|

Novel Vessels and Equipment

Primary vessels types that are used for both wind farm installation and O&M need to be more efficient; LEANWIND aims at developing new solutions for vessels currently in use and at designing new vessels - tailored to meet industry requirements. See the executive summaries of:

Upcoming executive summary due at the end of May 2017 on www.leanwind.eu/results: “Final novel maintenance vessel, access systems and installation vessel concept design package” (D3.5)

|

Operation and Maintenance strategies

O&M phases in the offshore wind farms are crucial. Procedures need to be optimised, especially in the far-shore, in deep water and other more exposed locations. This package of activities also wants to reduce OPEX costs by improving condition monitoring and remote presence systems, in order to minimize the need for on-site corrective maintenance. See the executive summaries of:

Upcoming executive summary due at the end of May 2017 on www.leanwind.eu/results: "Optimisation algorithms for dynamic scheduling of preventive and corrective O&" (D4.6)

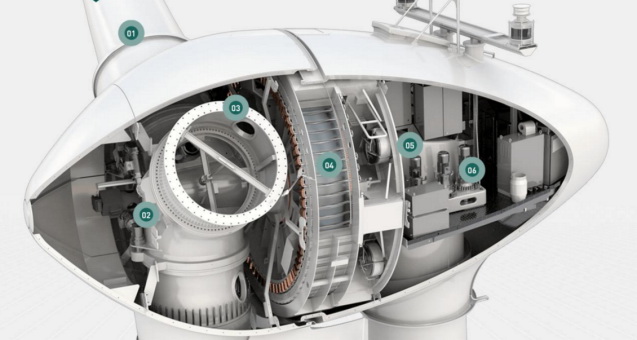

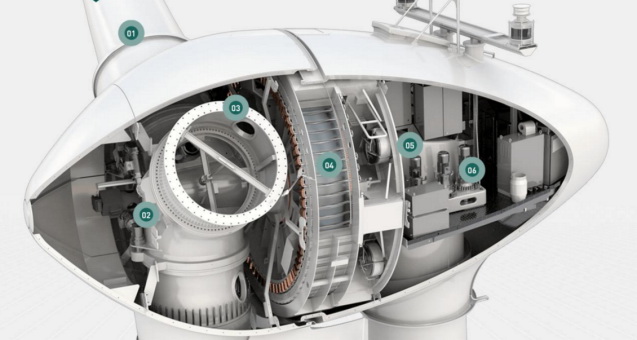

LEANWIND approach to condition and monitoring and diagnosis/prognosis of faults in offshores wind turbines: the main objective of LEANWIND Task 4.4 was the design, development and commissioning of an online system for condition monitoring and diagnosis/prognosis of faults in off shore wind turbines. The developed software is flexible enough to facilitate its use by different wind farm operators with different exploitation policies and business concepts. It also has the capacity to manage (i.e. receive, store and analyse) public and private datasets and also allows to modify over time some software pieces (scripts) to keep them updated.

After a complete state of the art analysis on Wind Turbine Diagnosis and Prognosis methodologies, International Standards and internet based programming tools, the option selected was to develop a “web service with scripting and data management capacities”. This option mixes the latest industry applicable methodologies of Fault Diagnostic and Prognostic, recommended by international standards, with the most updated advances in web services, putting together the best knowledge of the industry and the best digital technology in a unique and new software piece. |

Integrated Logistics

The final cost of energy produced by off-shore wind farms can be reduced by rendering the whole logistics system more efficient throughout the wind farm supply chain lifecycle – from installation and O&M to the decommissioning phase. The use of lean principles will help in defining the key industry challenges, analysing the separate parts composing the offshore wind supply chain – such as on-land transport and ports- and optimising them. Work under this set of activities has been completed and includes

- Reports describing the important characteristics of the offshore wind transportation and logistics system, defining a basis for the development of logistics decision support tools.

- A Geographic Information System (GIS) providing a comprehensive database of manufacturing facilities, transportation links and port locations across Europe.

- Nine inter-connected optimisation models for all life cycle phases and supply chain legs resulting in a holistic set of decision support tools applicable to port logistics, offshore and on-land transportation for the offshore wind industry

See the executive summaries of:

|

System Integration

The results, developments and achievements of all the above-mentioned core sets of activities are brought together into a comprehensive approach that takes into account, once again, the entire lifecycle of the offshore wind farm from early logistics to dismantling and ensures transferability of results to the industry.

See the executive summary of:

Upcoming executive summary due at the end of May 2017 on www.leanwind.eu/results: “Roadmap for the integration of component innovations in large offshore wind farms/arrays” (D6.4)

|

Testing and Validation of Tools and Technologies

Integrated technologies and tools developed within the project need to be demonstrated and validated through simulation, field demonstration -using real full-scale projects- and case-study demonstration based on real data. This package of activities is fundamental to prove the successful applicability of new technologies and tools to the offshore wind industry.

Testing Offshore Trials:

An intense schedule of trial activities is taking place until the end of the project. These activities include installation for a Gravity Based Structure, a turbine lifting system and a remote presence robot for O&M. Offshore trials based on external parallel projects have been slower than expected due to delays and difficulties in those external projects, out of the control of the LEANWIND project.

Upcoming executive summaries - due at the end of August 2017on www.leanwind.eu/results:

- “Case study validation of combined economic and logistics tools” (D7.2)

- “Use of simulation for O&M and Installation phase scenarios” (D7.3)

- “Field testing activities report” (D7.4)

NAAS remote presence robot

VIVA test centre case:

- Pilot installation was performed at VIVA test centre from June 2015 to January 2016.

- Fixed device; proof of concept. (temperature (thermography), sound, vision)

- The results from this test has been analysed and presented at the EERA Deepwind 2017 conference, and is in the process of publication in the Energy Procedia journal.

Photo credit: NAAS

Bessakerfjellet Wind Farm (Norway) Enercon 2.3 MW (on development test (2016-2017)

- Fully equipped sensor platform

- Redundant HD cameras

- Redundant Thermographic cameras

- Redundant Microphones

- Mobile system (Approximately 3 meters of rail)

- Charging station

- Accurate positioning

- Factory Acceptance Test completed in March 2017 with some minor issues.

Awaiting availability for installation.

Photo credit: NAAS

For more information on the NAAS remote presence prototype, please visit the project website

PLOCAN/ACCIONA Construcción Gravity Based (GBS) installation

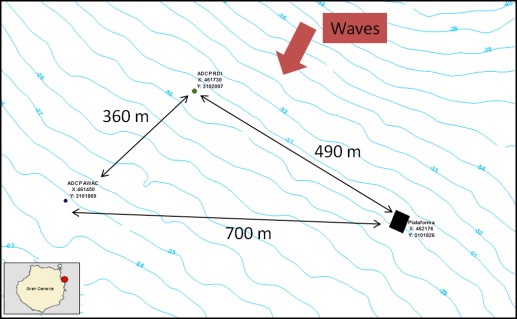

This offshore trial activity is based on a parallel project that will install a GBS offshore platform in the PLOCAN test site, in Gran Canaria. The installation of the platform was finally installed on November 30th 2016.

Photo credit: PLOCAN

ACCIONA Construcción carried out the following activities:

- Installation of pressure measurement sensors on GBS walls and bottom.

- Planning and installation of the solar panel energy system.

- Installation and testing of the acquisition data system (redundant system, two different portable hard drives).

- Configuration of both communication and data acquisition systems to obtain data wireless.

- The analysis of the data acquired between June and August revealed errors associated to six of the eight pressure sensors installed in the base slab of the caisson (problem is being fixed).

Photo credit: PLOCAN

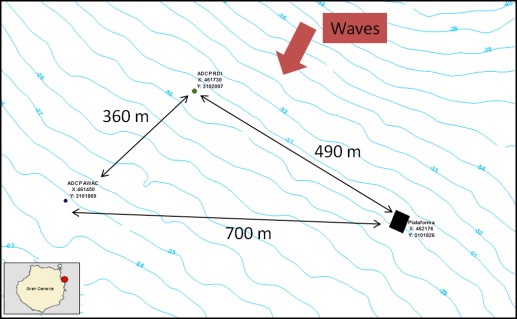

PLOCAN contributed with:

- Supervision of the GBS construction and commissioning.

- Inspection of the rock layer preparation and supervision of the marine operation

- Installation of 2 ADCP to measure the wave profile at the caisson location to correlate wave pressure at the GBS with wave heights.

Photo credit: PLOCAN

Collaboration with External R&D Projects

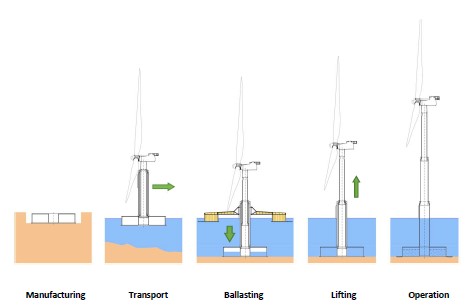

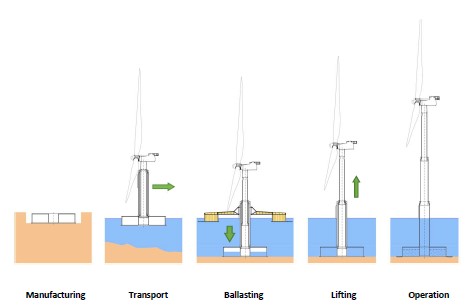

A relevant collaboration with the H2020 ELISA and ELICAN projects has been developed during this period. Both projects can share tools and validation data based on real offshore trials to be performed on the ELISA full scale demonstrator.

- The H2020 ELISA and ELICAN projects are coordinated by ESTEYCO. The aim of the projects is the construction and installation of a new self-installing self-buoyant telescopic foundation for a 5MW offshore wind turbine.

- The GBS has already been constructed at the Canary Islands, the tower and floater are in fabrication process and the 5MW wind turbine in process of delivery. The expected installation date is mid 2017 at the PLOCAN test site.

Photo credit: ELICAN |

Economic and Market Assessment

The new results achieved by the project need to be placed in an economic context. LEANWIND demonstrates that system optimisations and technology innovations have direct cost-saving benefits from which the whole wind industry will benefit. Offshore wind business and economic models that may encourage new sources of investment need to be examined. Moreover, the aim of the Economic and Market Assessment phase is to develop an implementation strategy that will ensure LEANWIND’s solutions to be effectively implemented.

Read the Executive Summaries of:

- “New Offshore Wind Business Models, Financing and Risk Assessment” (D8.1)

“Assessment of existing market impact and market creation potential of project innovations” (D8.4) - The LEANWIND project has generated innovative solutions for the offshore wind energy market to achieve its objective of cost-reduction in the industry. This report assesses the extent to which these innovations meet the requirements of stakeholders in the industry and, using attribute matching, assesses the extent to which innovations add value in the most critical aspects of the use or buy decision. This is achieved using a survey of industry stakeholders.

Upcoming executive summary due at the end of May 2017 on www.leanwind.eu/results: “Potential positive or adverse environmental and social impacts of project innovations” (D8.5)

|

|

|

|

LEANWIND will present its results at:

- ALL-ENERGY conference and Exhibition, 10-11 May 2017, Glasgow, UK

GDG will present foundation design outcomes

- 2nd Annual Offshore Wind Operations and Maintenance Forum, 30-31 May 2017, London, UK

UCC, SINTEF, University of Portsmouth, Aalborg University, Lloyd’s Register and Norsk Automatisering will showcase the work undertaken in relation to O&M

UCC, SINTEF University of Portsmouth, Aalborg University, Lloyd’s Register and Norsk Automatisering will showcase the work undertaken in relation to O&M at a special workshop (15:30-17:30, 31st May) including:

- Service Operations Vessel Design Concept

- Remote Presence Prototype

- Application of LEANWIND O&M strategy model

- Dynamic scheduling of preventive and corrective O&M

- Risk-based methodology and framework for O&M

- Conditioning monitoring software

- "Innovative solutions for an efficient wind farm supply chain", 6 June 2017, Capital Suite Room 16 (level 3) side event at Offshore Wind Energy 2017, 6-8 June, London, UKThis event will provide examples of innovative technologies, such as new vessel designs and novel substructure concepts, with the aim of improving the efficiency of the offshore wind farm supply chain and making it more cost competitive with traditional forms of energy.

- "A (c)lean energy transition - Innovative approaches to the offshore wind supply chain" (Energy Day - 20 June, Brussels, BE at the EU Sustainable Energy Week)

This “Energy Day” will present the benefits Europeans can have from the LEANWIND innovative approach principles to the offshore wind farm lifecycle and supply chain. More in particular, the market, environmental, and socio-economic perspectives will be analysed. The case study of Port of Oostende, in Belgium, will be presented as a concrete example.More information on the event and how to attend at http://www.leanwind.eu/events/

INDUSTRY INVOLVEMENT

The project’s Industry Advisory Group (IAG) is informed about the project's progress and gives advice throughout the whole project lifecycle. The IAG has provided so far very useful feedback on the direction of the research, helping to ensure that the focus is always industry relevant.

The IAG consists of Statoil (Norway), Statkraft (Norway), Siemens (Germany), Senvion (Germany), The Crown Estate (United Kingdom), Mainstream Renewable Power (Ireland) and DNV Kema (Norway).

Very relevant feedback on the project outcomes is also provided by members of WindEurope’s Offshore Wind Working Group, composed of relevant stakeholders active in the offshore wind sector.

KEEP IN TOUCH!

Should you have any questions or simply want to know more about LEANWIND, do not hesitate to get in touch with us: [email protected]

Find us on Twitter.

All information can be found at: www.leanwind.eu |

|

|

|

|

|