Read the Executive Summary of “TRL approach results for selection of installation vessel, maintenance vessel, access system and lift operations concepts” (D3.3)

Operation and Maintenance strategies

O&M phases in the offshore wind farms are crucial. Procedures need to be optimised, especially in the far-shore, in deep water and other more exposed locations. This package of activities also wants to reduce OPEX costs by improving condition monitoring and remote presence systems, in order to minimize the need for on-site corrective maintenance.

Read the Executive Summary of “Optimised maintenance and logistic strategy models” (D4.2)

Read the Executive Summary of “Remote presence prototype development” (D4.3)

Improving operation and maintenance of offshore wind with remote presence

The remote presence solution developed within LEANWIND by NA.AS is intended to be a low-cost method for checking the status of wind turbines to better know their condition and support decision making. Although useful for all turbines, this is especially beneficial to offshore turbines where reducing the need to travel to the site to do inspections are costly, time consuming and weather dependent.

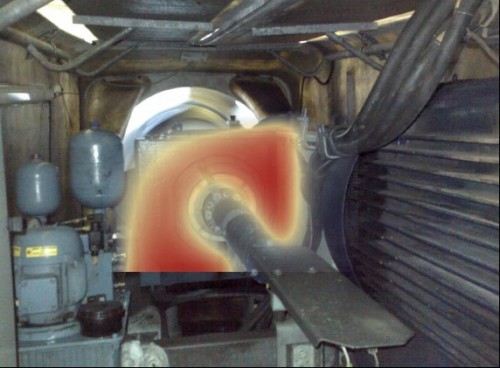

The system consists of an instrumentation platform that moves on a rail installed inside the turbine and observe it on behalf on operators on land. Information can be gathered while the system is remotely controlled by an operator on land, or automatically without human intervention. Existing condition monitoring systems typically measure vibration, temperature and performance data. Remote presence have a different approach, and focus instead on information similar to what an operator on site would observe, e.g. video, sound and thermographic imaging.

A pilot installation of a stationary version of the system was performed in June of 2015, and ran for 6 months. A new test with a fully featured version of the system, shown in the picture below, is planned for autumn of 2016. This will be installed on a rail inside a turbine, and operate similarly as a commercial product.

Source: NA.AS

Source: NA.AS

Source: NA.AS

Source: NA.AS

An example of image, enhanced with information from the thermographic camera

Integrated Logistics

The final cost of energy produced by off-shore wind farms can be reduced by rendering the whole logistics system more efficient throughout the wind farm supply chain lifecycle – from installation and O&M to the decommissioning phase. The use of lean principles will help in defining the key industry challenges, analysing the separate parts composing the offshore wind supply chain – such as on-land transport and ports- and optimising them.

Read the Executive Summary of “GIS database of manufacturing facilities, transportation links and port locations” (D5.2)

Read the “Ports suitability assessment for offshore wind development -Case studies report” (D5.3)

Read the Executive Summary of “Study of on-land transport system limitations” (D5.4)

Read the Executive Summary of “Decision making model for port layout/ configuration selection” (D5.5)

Read the Executive Summary of “Mathematical optimisation models and methods for transport systems” (D5.6)

A Full logistics model demonstration, including a demonstration of the GIS database, and Models for ports suitability assessments will be presented on 8 September at the first Stakeholders Showcase event, in Oostende.

For more details, please see the “Key Events” section below.

Economic and Market Assessment

The new results achieved by the project need to be placed in an economic context. LEANWIND demonstrates that system optimisations and technology innovations have direct cost-saving benefits from which the whole wind industry will benefit. Offshore wind business and economic models that may encourage new sources of investment need to be examined. Moreover, the aim of the Economic and Market Assessment phase is to develop a commercialisation and implementation strategy that will ensure LEANWIND’s solutions to be effectively implemented.

Read the Executive Summary of “New Offshore Wind Business Models, Financing and Risk Assessment” (D8.1)

KEY EVENTS

This 1-day event will take place in the Hotel Andromeda, Oostende, Belgium, and will showcase how ports can contribute to optimising the supply chain for an offshore wind farm. Notably, it will present project work to improve on-land and port logistics as well as innovative turbine and foundation installation strategies.

One of the highlights of this event will be a presentation of the experience of transformation undergone by the Port of Oostende, which has vowed to becoming the Flemish service port for the blue growth economy.More details on the event agenda.

A boat tour of the port installation, training and O&M facilities (14:40-16:30) will allow the participants to get a little taste of the functioning of an offshore wind park and concretely evaluate the added vale it can bring to harbour authorities and the local communities.

Participants arriving the night before are also invited to a drinks reception (18:00 - 19:00, Hotel Andromeda - C-Bar Piano Lounge) and a dinner (19:00 - End, Ostend Queen, Kursaal Weshelling 12 - 8400 Ostend).

Kindly note that participation is free of charge.

For logistical purposes, we would appreciate it if you could register.

Check here for any accomodation suggestion.

Offshore wind farm lifecycle and supply chain: assessing local impacts

September 28th, 2016, 11.30 - 13.00. Hamburg, Germany.

As part of the WindEurope Summit 2016, this session will present an analysis of possible positive and adverse environmental and socio-economic impacts that the application of “lean” principles in the offshore wind farm lifecycle and supply chain can generate on local environment and communities.

It will also provide the case study “Port of Oostende” to highlight the role ports play in a local community and show the challenges and rewards of port insertion in a lean offshore wind supply chain.Finally, the session will present the progress of the more holistic economic model the study will convey to. This aims to assess both the possible costs savings deriving from the novel approach applied and the industry uptake of the innovations generated.

Please be aware that access to the event is only possible if you possess a one-day pass for the WindEurope Summit 2016.

We would appreciate it if you could notify us your attendance by filling in this form.

INDUSTRY INVOLVEMENT

The Industry Advisory Group (IAG)

The project’s Industry Advisory Group (IAG) is informed about the project's progress and gives advice throughout the whole project lifecycle. The IAG has provided so far very useful feedback on the direction of the research, helping to ensure that the focus is always industry relevant.

The IAG consists of representatives of: Statoil (Norway), Statkraft (Norway), Siemens (Germany), Senvion (Germany), The Crown Estate (United Kingdom), Mainstream Renewable Power (Ireland) and DNV Kema (Norway).

KEEP IN TOUCH!

Do not miss our upcoming publications!

You will soon be able to read executive summaries of:

- "Fixed Platform Design Framework" report (D2.4)

- "Floating Substructures Design Framework" report (D2.5)

- "Novel maintenance vessel, access systems and installation vessels design" report (D3.4)

- "Holistic supply chain optimisation model" report (D5.7)

Should you have any questions or simply want to know more about LEANWIND, do not hesitate to get in touch with us: [email protected]

Find us on Twitter.

More information available at: www.leanwind.eu